saving water

We are committed to continuously monitoring and optimizing our water consumption across all areas of operations. Our approach ensures that water resources are utilized efficiently, including implementing advanced technologies and strategies to reduce water usage and maximize water reuse and recycling.

goal

performance

By 2030, we aim to reduce our freshwater withdrawal by 21% per 1,000 m² of net saleable paper compared to our baseline 2023.

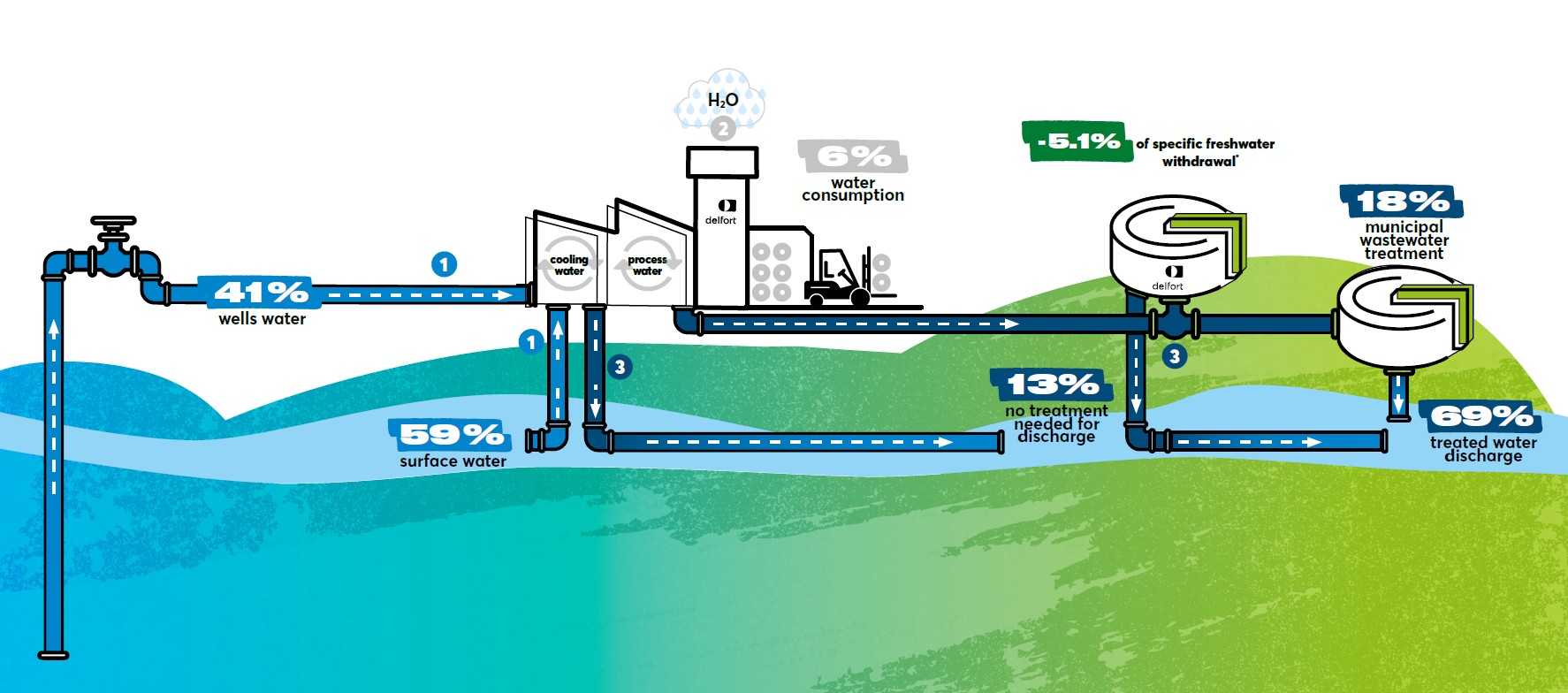

In 2024, we decreased our specific freshwater withdrawal by 5.1% per 1,000m² of net saleable paper compared to our basline 2023.

water stewardship

At delfort, water is used in various applications such as process water, cooling water and feed water for boiler houses. While water is essential for paper production, it is only used for cooling purposes and personal hygiene in converting operations. The production of high-quality specialty paper requires pure water, resulting in biological and physical limitations for closing water cycles in the mills.

Our continuous investments in efficiency improvements based on water balance analyses, smart water technology and process optimizations will help us further reduce our water withdrawal.

our actions in 2024

water management

Our water stewardship strategy focuses on closing cycles through water recycling and reuse, minimizing environmental impact through continuous water-saving measures and improving wastewater treatment. This strategy is supported by a systematic approach to risk assessment and management, alongside ongoing monitoring and improvement of water withdrawal, consumption and discharge.

Our 2024 water withdrawal, consumption and discharge figures

(1) water withdrawal

Our water sources are groundwater from our own wells and surface water. As our high-quality papers require extremely pure water, we treat extracted water prior to use to prevent the introduction of any impurities. We apply the WRI Aqueduct Water Risk Framework and the WWF water risk filter to determine water risk and evaluate water stress on all our sites that depend on high volumes of water.

We continuously invest in water efficiency projects, process optimization and Best Available Techniques (e.g. waste water heatpump evaluation) to reduce our water withdrawal volumes.

(2) water consumption

We differentiate between usage and consumption of water. Our water consumption reflects the water evaporated during the drying process and the water content in the specialty papers we produce. Water usage refers to cooling water and process water.

We keep cooling water in separate circuits to reduce freshwater withdrawal and use the warm water for internal processes. We reuse clarified water to clean our paper machines, minimizing the freshwater consumption of our mills. Our goal is to further separate the cooling and process water cycles to improve efficiency. We conducted a comprehensive water balance analysis at two of our sites to identify opportunities for optimizing water usage in both cycles.

(3) water discharge

Wastewater that is purified before discharge is primarily generated from stock cleaning after machine downtime or grade changes, process water and white water from wire and felt cleaning.

We have on-site tertiary wastewater treatment plants and a primary treatment plant, all of which adhere to the highest environmental standards. All water discharged from paper mills is continuously monitored. Some paper sites discharge water to freshwater bodies and surface water. Monitoring this water ensures that discharges are always well within the limits for each production site, in compliance with applicable standards and regulations. On other sites the wastewater is discharged to municipal wastewater treatment plants.

monitoring and compliance

We regularly monitor wastewater quality parameters based on water mass balances available at each site. Key parameters, such as pH value and temperature, are continuously measured. Automatic water sampling ensures daily analyses of parameters such as chemical oxygen demand (COD), solid content and biological oxygen demand (BOD).

We adopt a precautionary approach and prepare for potential incidents through emergency plans that are easily accessible to all employees. These comprise precise procedures in the event of water contamination and corresponding instructions for action. Additional buffer tanks or ponds protect against the discharge of wastewater into the sewer system or the environment.

applying industry standards

- ISO 14001 (environmental management)

- IPPC Integrated Pollution Prevention and Control

- WWF Water Risk Filter

- WRI Aqueduct Water Risk Framework