what it takes to develop fit-for-purpose barrier paper packaging solutions

In an era where environmental consciousness is no longer a choice but a necessity, companies are seeking ways to transition from hard-to-recycle, non-renewable packaging to recyclable alternatives. Along with our R&D partner delsci, we support companies in becoming leaders in sustainable packaging. Our range of flexible barrier paper packaging combines functionality with sustainability providing forward-thinking packaging solutions for a wide range of food and non-food uses.

Fit-for-purpose packaging aims to strike a balance between functionality, sustainability and regulatory compliance and is well-suited to its intended purpose. The barriers applied to paper packaging must often fulfill a variety of requirements.

barrier paper packaging that is fit-for-purpose

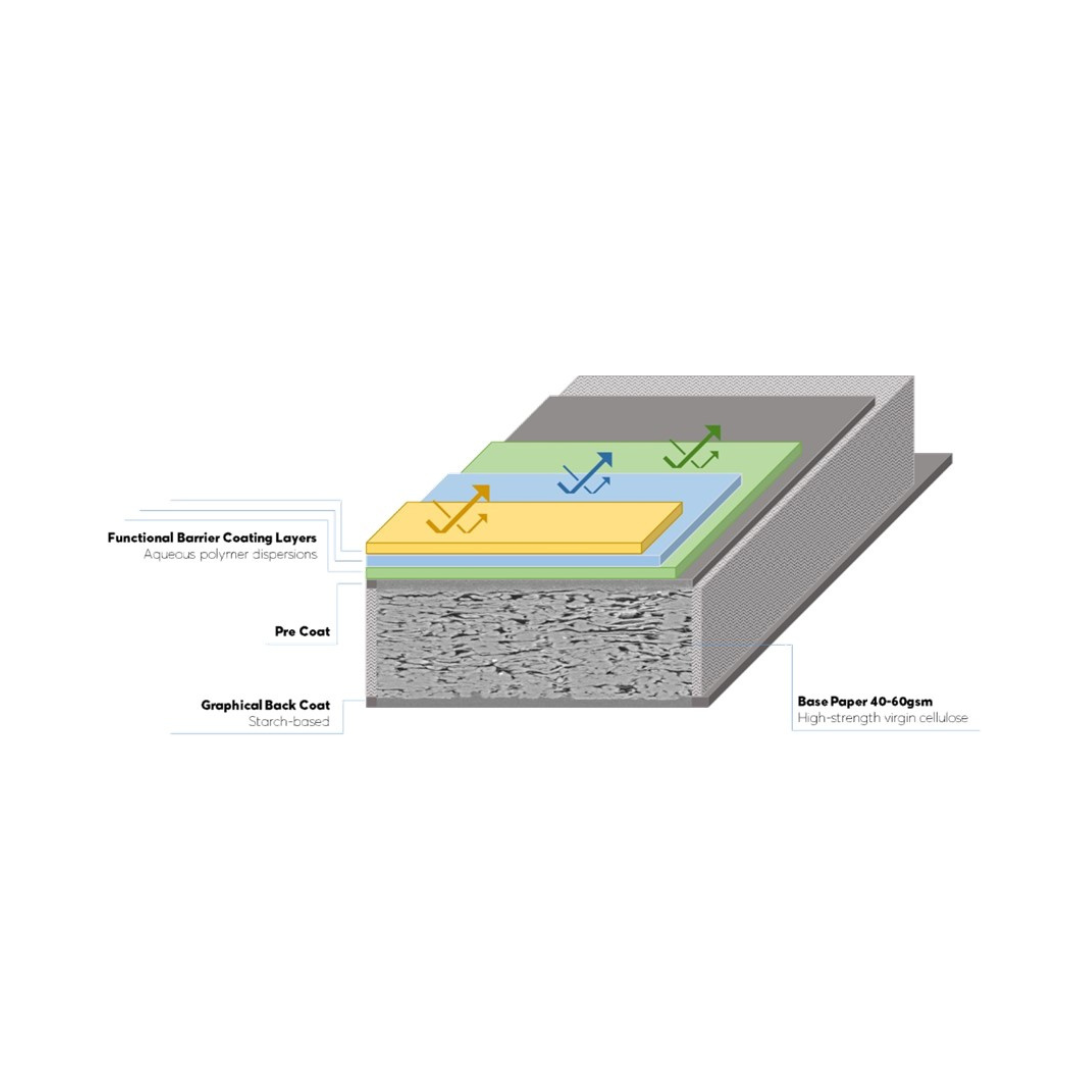

Especially when it comes to food end uses, barrier papers must meet demanding requirements to adequately protect the product, maintain product freshness and hygiene and meet industry and consumer demands. Multiple barrier layers make it possible, when applied correctly, to meet these demands.

Our expertise lies in optimizing barrier layers without over-engineering the packaging. This requires a profound expertise in materials science, engineering and innovative design. We work diligently to find the right combination to provide the necessary functionality while maintaining the recyclability of the packaging.

experts in developing barrier paper packaging

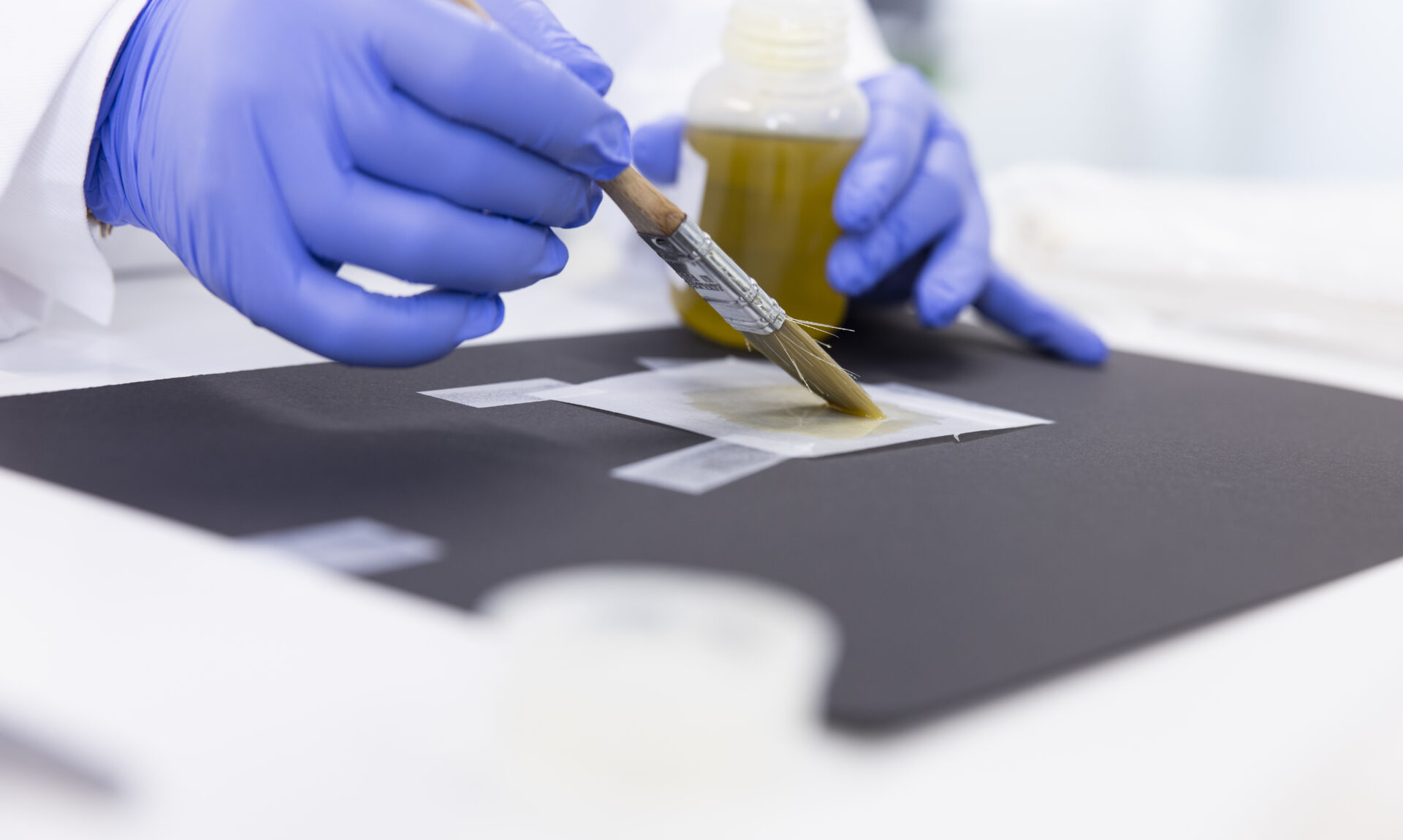

To develop the right fit-for-purpose barrier for each unique application we use agile testing and development, led by a team of more than 20 paper scientists and product developers, in our state-of-the-art coating laboratory.

the perfect synergy between paper substrate and barrier layers

Our range of on-site testing allows us to quickly test and adjust paper substrate, coating technology and application technology to find the winning combination. When developing a barrier coating, the following is taken into account amongst many other features:

what it takes to develop the optimal barrier paper packaging solution

- The composition to maximize the bio-content of our dispersion coating formulations. Bio-based barriers are derived from renewable resources, such as plant-based materials like cellulose or starch. By using these resources, the environmental impact is reduced compared to barriers sourced from fossil fuels or non-renewable materials.

- The thickness of each barrier layer must be precisely controlled. Too thick, and it may impede the packaging's recyclability, add unnecessary weight, or affect the flexibility of the packaging. Conversely, if the layers are too thin, they might not provide adequate protection, rendering the packaging ineffective.

- Ensuring that our coatings run seamlessly on our production lines is essential. To achieve this, we meticulously optimize the composition between fibers, fillers, pigments, additives and coating chemistry. This not only enhances runnability but also contributes to the overall efficiency of our packaging production process.

- Achieving the right design for pre-coat and top-coat layers, both online and offline, is critical. These layers ensure that our barriers can withstand the rigors of handling, transportation and consumer use without compromising their integrity.

- The harmonious interplay between the selected coatings and the base paper is a vital consideration. Our experts meticulously evaluate the right base paper and surface treatment to ensure that they complement and enhance the barrier's performance.

- Optimization of multiple barrier layers to achieve functionality without over-adding barriers. Overly complex or layered barriers can make paper packaging more challenging to recycle and add unnecessary costs to the product. We are pioneers in developing barriers that do not negatively impact the recyclability of the packaging.

- Ensuring uniform application of each barrier layer across the entire packaging surface. Variations in layer thickness or application inconsistencies can lead to performance troubles, such as weak points in the barrier or uneven protection.

let's find your perfect solution!

Interested in switching to functional and recyclable barrier paper packaging?

We would love to hear from you! For inquiries, collaborations, or a tour of our Packaging Laboratory, please don't hesitate to contact us.

Herwig Kirchberger, Managing Director · DELSCI

Herwig.Kirchberger@delsci.com I +43 7229 776-552

deslci is a research organization that invents smart paper packaging solutions for food and consumer goods applications. We're a team of scientists and technologists on a mission to empower people to consumer responsibly. This means replacing plastic (wherever possible) with functional paper that works harder than ever before and helps protect the environment.

this could also be interesting for you

let's talk!

With out specialized expertise and deep knowledge in designing lightweight barrier paper packaging, we're not just your partners we're your catalysts for change, your collaborators in innovation.

Contact us and join the paper revolution today!