concept to shelf: shelf-life testing facility for barrier paper packaging

From concept to the shelf! delfort, in collaboration with R&D partner deslci, has expanded our cutting-edge coating laboratory, introducing a comprehensive shelf-life testing facility. This expansion underscores our dedication to assisting customers in their transition to barrier paper packaging. By enhancing our in-house packaging development and adding shelf-life testing, we address the dynamic needs of the ever-evolving packaging landscape.

We understand the growing demands for recyclable packaging solutions made from renewable materials and we’re meeting these needs head on. With our new in-house shelf-life testing capabilities, we offer our clients comprehensive support throughout the development process, from concept to market-ready packaging. The laboratory is designed and equipped to support us in our efforts to design lightweight, functional and sustainable barrier paper packaging.

a comprehensive approach to packaging development and shelf-life testing

Adopting a comprehensive approach to packaging development, we make mock-ups of barrier paper packaging tailored to a diverse range of food and non-food applications based on our clients' specific requirements.

mock-ups and barrier testing

The barrier quality of our packaging is examined in detail from the reel to the final package, ensuring consistent performance and reliability of the barrier. We ensure that our barriers are functioning properly at each stage. We test that our barriers are not removed, rubbed off, or cracked during packaging, filling, or shipping with simulation testing. Beyond mock-ups, we can also create and test small series paper-flow packs.

runnability testing and machine optimization

In the transition to fiber packaging, adjustments are sometimes necessary on packaging machines to accommodate different packaging materials. Collaborating closely with machine suppliers and builders, we identify the parameters requiring modification on existing machines to ensure the smooth operation of our barrier paper packaging. By comprehending the mechanics of packaging machines and optimizing machine components for barrier paper, we enhance the runnability of our papers.

sealability testing and optimization

We identify opportunities to optimize folding and sealing techniques while pinpointing where enhanced barrier properties are needed most. Since paper is not as soft as other materials, there can be challenges for the sealing jaws of paper machines when they must seal more than two layers of paper together. We help in the paper design by considering the folding and sealability requirements of the final packaging and by adding thicker coatings, where necessary, to improve sealability.

shelf life testing

Our laboratory is fully equipped to conduct rigorous shelf-life testing. We can assess and optimize packaging to maintain the freshness and quality of products, ultimately extending their shelf life and reducing food waste.

qualifying the shelf-life abilities of paper

Our goal is to establish a standardized method to qualify the shelf-life abilities of our paper for different food categories. We measure with different temperatures and humidity conditions and track fat staining, gas diffusion and aroma. This allows us to accelerate the qualification process by giving our customers proof that our barrier paper works for different types of food. Our range of shelf-life testing includes:

- Accelerated shelf life tests

- Leak Testing

- MAP (modified atmosphere packaging) Testing

- Quick Tests on MVTR, OTR, OGR to quantify HFFS impacts at reel level and packaging level

- Supply chain fitness testing and drop tests

- Microbiological basics

- Food safety

-

Expertise

Our team of experienced professionals boasts a wealth of knowledge and experience in the packaging industry, ensuring that your project is in capable hands.

-

Cutting-Edge Technology

Our laboratory is equipped with the latest technology to conduct precise testing and analysis, resulting in packaging solutions that exceed industry standards. Our paper-based packaging solutions are eco-friendly and designed to reduce your environmental footprint.

-

Comprehensive Support

From concept and design to testing and optimization, we offer end-to-end support for your packaging needs. Over the years, we have consistently delivered innovative packaging solutions that have propelled our clients to success.

join us in the packaging revolution!

We're not just offering packaging solutions; we're providing a partnership. We are your ideal development partner for barrier paper packaging. For inquiries, collaborations, or a tour of our laboratory, please don't hesitate to contact us.

Interested in switching to function paper packaging?

For inquiries, collaborations, or a tour of our Packaging Laboratory, please don't hesitate to contact us.

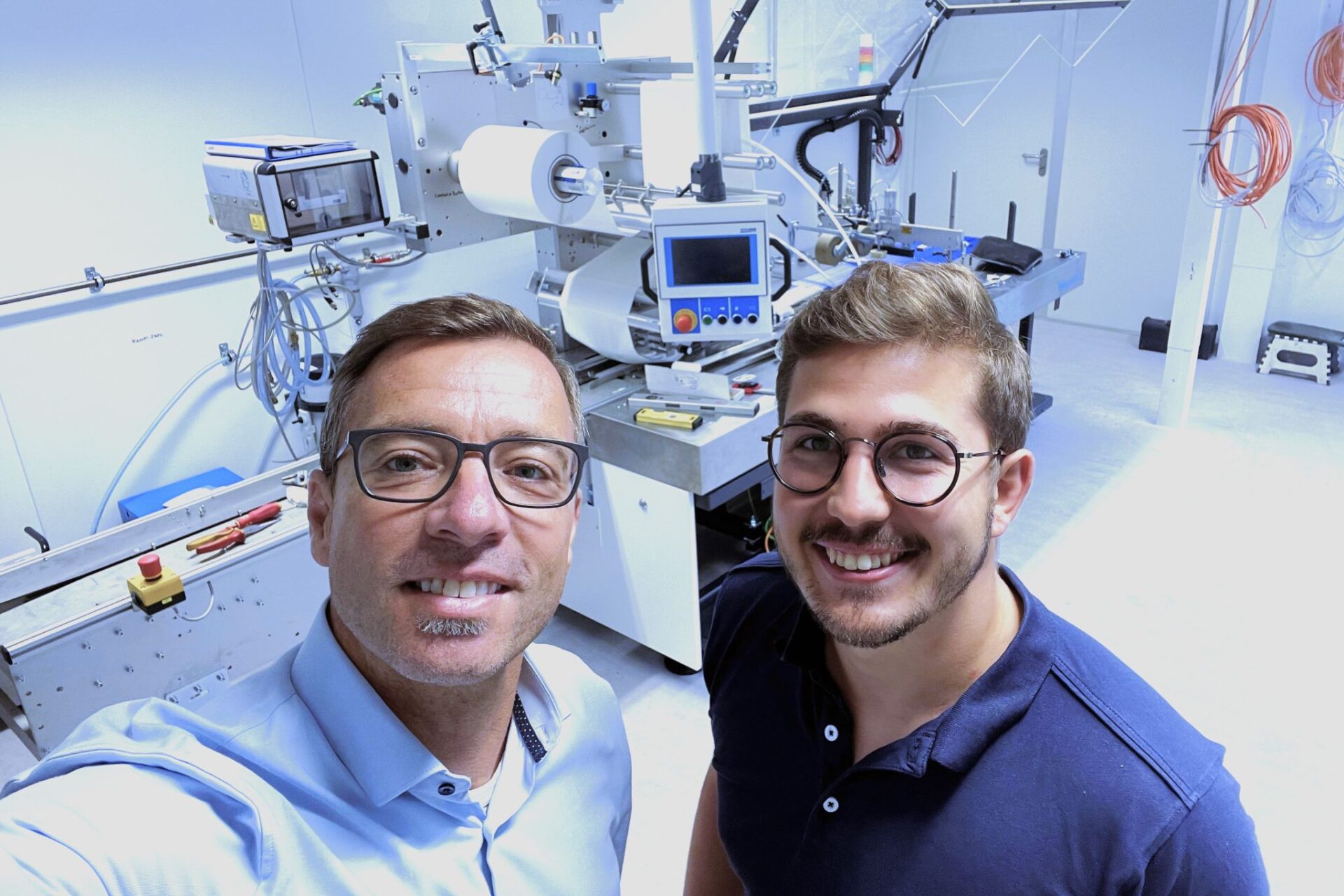

Herwig Kirchberger I Managing Director at delsci

herwig.kirchberger@delsci.com I +43 664 88375438

Simon Tüchler-Dorfner I R&D Manager Packaging at delsci

simon.tuechler@delsci.co I +43 664 88505540

this may also be interesting for you

Let's talk

With our specialized expertise and deep knowledge in designing lightweight barrier paper packaging, we're not just your partners we're your catalysts for change, your collaborators in innovation.